About BraMHanee

BraMHanee Industries is established by Entrepreneurs who have a combined experience of over 53 years in the field of CNC Router Manufacturing, Quality Control, Project Management and Sales and Marketing. We have embarked on a road map full of opportunities and challenges and firmly on the way of becoming pioneer in offering Precision Cutting, Bending and Fabrication Solutions for Industry and Interior/Exterior Decoration in Central and West India.

BraMHanee Industries started therir operations by importing high end CNC WaterJet Cutting Machine from S. Korea in 2015. We established market for its services in Maharashtra, Madhya Pradesh, Chhatisgarh and Orrisa by giving timely and quality services to clients of Industry and Interior/ Exterior Decoration.

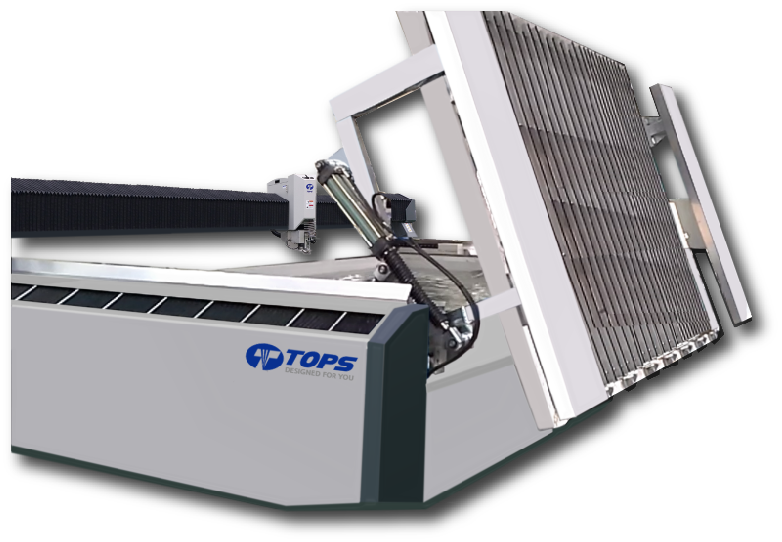

Understanding the need of the hour, and to leverage our position in the cutting industry, we expanded our precision cutting facility by importing 1 KW CNC laser cutting machine from China in 2018. This machine took no time to run to its full capacity.

To further meet our market demand, we have imported a 3 KW laser cutting machine from China. We have also imported a CNC automatic Bending machine and MIG welding machine to start basic fabrication works.

Currently, we are operating out of a 5500 sq feet work-shop facility in MIDC, Butibori, Nagpur and a Marketing Office in Central Nagpur. We plan to purchase a bigger land and contruct a scalable three story factory/office building to meet our current and future requirements.